Guard rails serve a crucial purpose in industrial and public settings by preventing falls and directing people and vehicles away from dangerous areas. But what exactly are these ubiquitous safety barriers made of? This comprehensive article will analyze the key materials used in guard rail construction.

Key Takeaways:

- Guard rails are typically constructed using steel, stainless steel, wood, or galvanized steel.

- Fabricated steel is the most common material for industrial guardrails.

- Stainless steel offers enhanced durability but higher cost.

- Wood remains a frequent choice for guardrails in some settings.

- Galvanized steel is standard for highway guardrails and road barriers.

Introduction: Why Does Guard Rail Material Matter?

Guardrails and safety railings provide an invaluable protective barrier in industrial work zones, public spaces, roads, and many other settings. They prevent falls from dangerous edges and redirect pedestrians, workers, and vehicles away from hazardous areas. But in order to reliably perform these critical functions, guard rails must be constructed from strong, durable materials able to withstand years of use, exposure to the elements, and occasional impacts. So what exactly are guard rails made from?

The selection of appropriate materials is an essential consideration in guard rail engineering and design. The material must have sufficient strength to meet safety standards while still being cost-effective. This article will provide a comprehensive overview of the advantages, applications, and composition of the most common materials used in guard rail fabrication. It will empower readers to make informed choices regarding guard rail materials for their specific needs.

The Major Materials Used in Guard Rail Construction

Guard rails feature diverse designs to serve different purposes, but most are fabricated from a selection of metal alloys or finished wood. The prime materials used in guard rail manufacturing include:

Fabricated Steel: The Industrial Guard Rail Staple

Fabricated steel is the predominant material used in safety guardrails for industrial facilities and work zones. Steel combines high strength, durability, and economical cost. This makes it an ideal choice for the guardrails used in factories, warehouses, construction sites, and other commercial and agricultural locations.

Popular examples of fabricated steel guardrail systems include:

- Armco: Armco steel guardrails feature a simple, bolt-connected design. The prefabricated sections offer quick and easy installation. Armco systems comply with OSHA and ANSI safety regulations.

- Kee Klamp: Kee Klamp steel railing components allow for customized guardrail designs. The pipe-based parts utilize a clamp-style connection system for versatile arrangements and quick fitting.

- Modular Pipe Guardrail: These sturdy guardrails utilize horizontal steel pipes as top rails, combined with vertical pipe posts. They offer simple installation and reconfiguration.

Steel guardrails deliver the ideal balance of strength, durability, safety, cost-effectiveness, and convenience for industrial applications.

Stainless Steel: Enhanced Durability and Corrosion Resistance

While fabricated steel is one of the most common choices, stainless steel offers a more corrosion-resistant option. Stainless steel alloys like 304 and 316 steel contain chromium and nickel to prevent rusting and discoloration.

Although more expensive upfront, stainless steel guardrails deliver superior long-term value through exceptional durability and low maintenance needs. Their enhanced corrosion resistance allows them to better endure outdoor placement and humid, coastal, or chemical-heavy environments.

Stainless steel is frequently recommended for guardrail installations in settings like:

- Chemical and pharmaceutical facilities

- Desalination plants

- Offshore oil rigs

- Marine ports and docks

- Swimming pools

- Public parks and beaches

For applications where longevity and low maintenance are priorities, stainless steel guardrails can justify their higher initial cost over the long run.

Wood Guardrails: A Traditional Aesthetic

While metal dominates industrial guardrails today, wood guardrails remain popular in some public and residential settings. Wood offers a traditional, attractive aesthetic for applications like:

- Porches, decks, and balconies

- Parks and trails

- Rustic cabins and lodges

- Residential stairways and landings

Cedar, redwood, and pressure-treated pine are common wood types used. Designs may utilize lumber guardrail posts and planks, or prefabricated guardrail panels and balusters. Compared to metal systems, however, wooden guardrails require more maintenance through staining, sealing, or replacing rotted components.

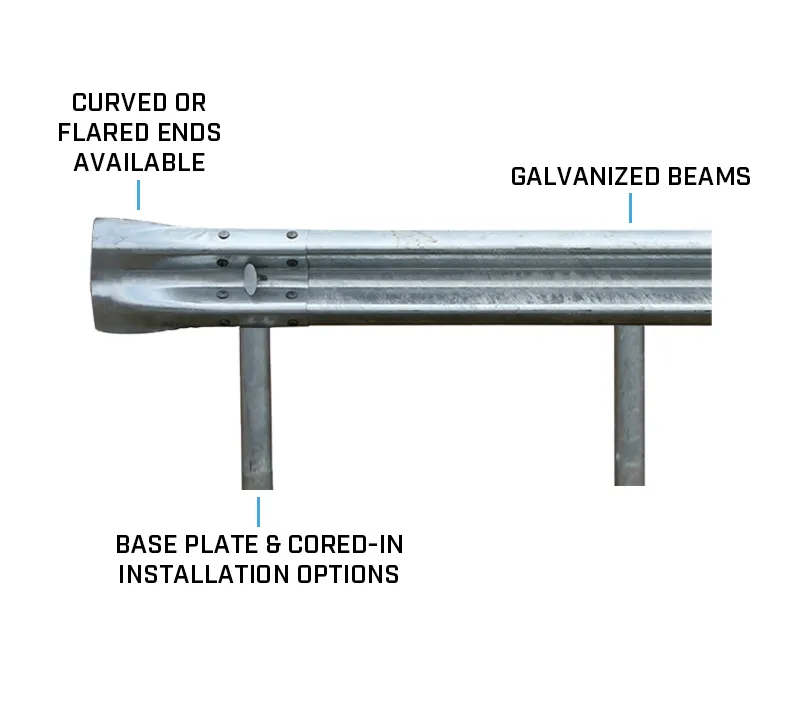

Galvanized Steel Highway Guardrails

Roadways utilize guardrails known as traffic or highway barriers. These redirect errant vehicles back onto the road and prevent head-on collisions in medians. Highway guardrails in North America are predominantly made of galvanized steel – an alloy with a protective zinc coating to resist corrosion.

Common designs include:

- W-beam rail panels

- Box-beam rails

- Cable and post guardrails

These galvanized steel barriers offer the strength needed to safely contain and redirect vehicles. They are approved for highway installations by transportation agencies. The galvanization provides extended outdoor durability across changing weather conditions.

The Best Materials For Specific Guard Rail Uses

In summary, the prime materials used in guard rail fabrication each offer particular advantages:

- Fabricated steel is the standard for industrial uses, combining strength, safety, and cost-efficiency.

- Stainless steel delivers superior corrosion resistance and durability in demanding environments.

- Wood provides a traditional look for residential and public settings.

- Galvanized steel meets the impact resistance and durability needs of highway barriers.

The ideal guard rail material depends on the specific conditions and requirements of the application. Engineers and safety managers must weigh factors like usage, environment, aesthetics, regulations, and cost when selecting appropriate materials. But regardless of the material used, proper guard rail installation is essential to deliver reliable protection.

Frequently Asked Questions About Guard Rail Materials

Guard rails are vital safety components found everywhere from warehouses to highways. But questions may arise regarding ideal materials for particular applications. Here are direct answers to some of the most common guard rail material questions:

What is the strongest material used for guardrails?

Steel offers the greatest strength for guardrail fabrication, with a high yield and tensile strength. Stainless steel types like 316 stainless provide enhanced strength over regular fabricated steel.

What material holds up best outdoors?

For outdoor guardrails, galvanized and stainless steel offer the best corrosion resistance and durability in weather exposure. Stainless steel grades 304 and 316 are most recommended.

Can you use aluminum for guardrails?

Aluminum lacks the strength of steel and is not approved for guardrails. Extruded aluminum railings are available but only for decorative purposes. Structural aluminum guardrails would deform under load.

Is wood an acceptable material for guardrails?

Wood remains a permitted material in building codes for residential settings. However, wood lacks durability and strength compared to metal. Frequent inspection and maintenance of wood guardrails are required.

What metals resist corrosion?

Stainless steel offers the best all-around corrosion resistance. Other alloys like galvanized steel, aluminum, and copper also resist corrosion in certain environments.

How are stainless steel guardrails fabricated?

Like other metals, stainless steel guardrail parts are formed through welding, bending, punching, cutting, and drilling. Grade 304 stainless steel is typically used. The rails can have a polished finish.

What makes galvanized steel good for highways?

The zinc galvanization gives steel enhanced corrosion resistance and durability in outdoor settings. This allows galvanized guardrails to maintain integrity across changing weather.

Can you paint wooden guardrails for durability?

Yes, paints and stains can preserve and protect wood guardrails. But regular reapplication is still needed. Wood rails require more maintenance than metal alternatives.

How often should metal guardrails be inspected?

Industry standards recommend inspecting metal guardrails at least annually. This checks for damage, rust, loose connections, or other issues compromising integrity.

Guard Rail Materials Must Balance Safety, Strength, and Cost

Guard rails provide an invaluable barrier keeping people and vehicles away from hazardous edges and openings. But these essential safety features can only perform properly if well-designed and fabricated from appropriate materials. Metal alloys and wood each offer particular benefits for specific guardrail applications.

Engineers must evaluate key factors like usage, exposure, longevity, aesthetics, and upfront and lifecycle costs when selecting the optimal materials. But regardless of the materials ultimately chosen, proper installation and maintenance practices are vital for any guard rail system to deliver lasting protection.

Comprehensive understanding of common guardrail materials and their strengths empowers safety managers and designers to make informed choices. Guard rails constructed using the right materials for their intended use will continue shielding people from harm year after year into the future.

- How Many Jobs Are Available in Computer Software Prepackaged Software?

- How to Apply Wella Color Charm to Wet or Dry Hair?

- Which Clif Bloks Have Caffeine?

- Can a Diabetic Eat Burgers?

- Why She Lives as a Villainess Manga?

- What Is the Purpose of Pre-tinning a Wire?

- What Does Anchorites Meaning? An In-Depth Look at the Ascetic Lives of These Religious Hermits

- Does Iron Attract Magnets?

- Where Are the Ergots on a Horse?

- Targeted Author Salman Rushdie Fights False Accusations on Twitter

- Can You Paint The Inside Of A BBQ Grill?

- Does Desdemona Lie to Othello?

- Can You Wear Hey Dudes Without Socks?

- Does Coffee Cause Acne? (Detailed Guide)

- Does Maestro Vibrola Stay in Tune??