Key Takeaways

- A turbocharger compresses more air into the engine’s cylinder, allowing more fuel and creating more power.

- It uses exhaust gas to spin a turbine connected to a compressor that forces extra air into the engine.

- Benefits include increased power, torque, and efficiency, especially at lower RPMs.

- Turbochargers are not always on, activating above certain engine speeds to deliver boost.

- Modern turbos have complex systems controlling gas flow for linear power delivery.

What Is a Turbocharger and How Does It Work?

A turbocharger is an engine component that allows more air to be delivered to the engine’s cylinders, enabling more fuel to be added and boosting the power from each combustion cycle. But how does a turbocharger accomplish this crucial task?

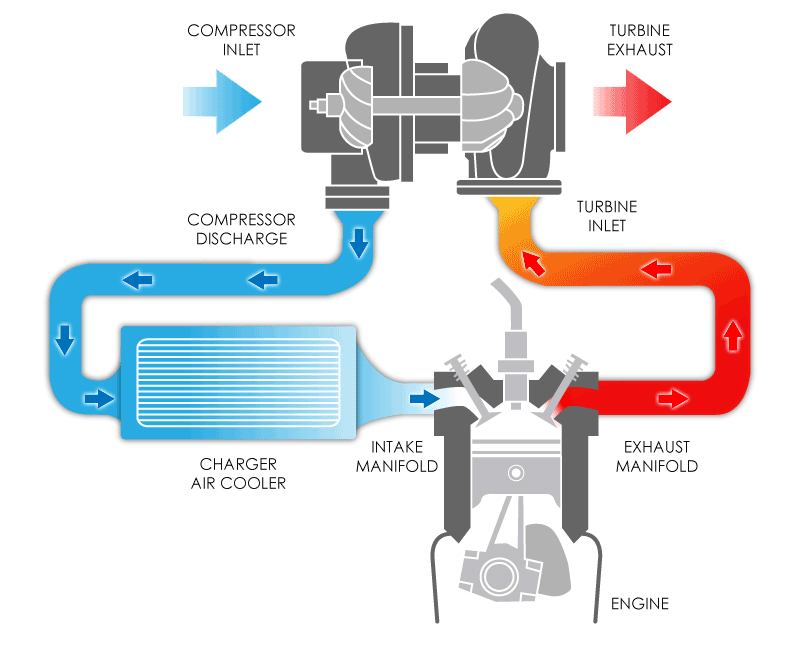

Essentially, a turbocharger is a forced induction system that uses the engine’s own exhaust gases to compress incoming air before it enters the cylinders. It is made up of two connected turbines – the exhaust turbine and the compressor. When the engine is running, exhaust gases are directed through the exhaust turbine, which causes it to spin rapidly. This exhaust turbine is connected by a shaft to the compressor turbine, so as the exhaust turbine spins, it causes the compressor to spin as well.

The compressor turbine is installed between the air intake and the engine cylinders. As it spins rapidly thanks to the connected exhaust turbine, the compressor turbine draws in ambient air and compresses it before sending it into the engine. This compression causes significantly more air molecules to be crammed into the cylinders when the intake valve opens.

With this greater mass of air in the cylinders, more fuel can be added as well. When ignition occurs, the larger air-fuel mixture creates a bigger explosion with higher energy, generating more force to drive the pistons down and producing greater engine power. This is how a turbocharger provides that distinctive power boost.

What Are the Advantages of Using a Turbocharger?

There are several key benefits that a properly utilized turbocharger can provide for an engine:

- Increased power output – By enabling more air and fuel in each cylinder, the larger explosions result in higher force to drive the crankshaft, meaning more horsepower sent to the drivetrain.

- Increased torque – Greater air density in the cylinders also boosts the rotating force exerted on the crankshaft, resulting in amplified torque, especially at lower RPMs.

- Improved efficiency – Pushing more air into the engine allows more fuel to be combusted to release energy, reducing waste and improving fuel economy.

- Better high-altitude performance – Thinner air at high elevations limits normally aspirated engines. A turbo compresses air to sea-level densities for optimal high-altitude operation.

- Emission control – The improved combustion of an engine with forced induction reduces exhaust pollutants versus a natural engine.

- Engine downsizing – Turbocharging enables smaller, lighter engines while providing power comparable to larger motors.

So in summary, adding a turbocharger allows smaller, more efficient engines to produce power similar to much larger motors. Drivers enjoy quick throttle response, ample low-end torque, and increased efficiency from the engine.

How Do Turbochargers Deliver the Extra Power?

Turbochargers are not always spinning and delivering compressed air to the engine. They only activate and begin to spool up once certain engine speed thresholds are met and exhaust gases acquire sufficient energy.

At low RPMs or under gentle acceleration, minimal exhaust gas flows through the turbo and the compressor turbine spins slowly – not enough to compress intake air. The engine operates normally with atmospheric pressure air induction. No boost is produced.

Once engine speed rises, the exhaust volume and velocity builds. This rapidly accelerates the exhaust turbine, which then spins up the connected compressor. The compressor draws in air and compresses it into the cylinders. Only now is boost created to augment engine power.

As RPMs continue climbing, exhaust flow energy further increases, spinning the turbo faster. This results in greater compression of intake air. Turbo speed, and therefore boost pressure, follows engine speed and load. The turbo works harder as the engine works harder, matching the extra air to the demands.

Modern turbocharger and engine management systems employ complex control strategies. Wastegates and blow-off valves regulate turbo speed and compressor output. Precisely calibrated fueling compensates for boost fluctuations. This allows turbocharged engines to deliver remarkably linear, predictable power across the rev range.

What Are Some Common Questions about Turbocharger Operation?

What causes turbo lag?

Turbo lag refers to the delay in power increase after the throttle is open. It happens because it takes time for exhaust flow to accelerate the turbo to start compressing air, creating a momentary lapse before the boost arrives. Variable vane or twin-scroll turbos minimize lag.

Do turbos increase fuel consumption?

Turbocharged engines require additional fuel to take advantage of the extra air. However, the increased efficiency balances this out, resulting in comparable or even improved fuel economy versus natural aspiration.

Can turbos be added to any engine?

Turbocharger systems can be retrofitted to many engines but require modifications like strengthened internals. Vehicles specifically engineered for forced induction are best suited for turbocharging.

Do turbos wear out over time?

Turbos can last the lifespan of a vehicle if properly maintained. However, lack of oil changes and overheating can eventually damage the precision bearings. Regular maintenance is key.

Why do turbos whistle?

The distinctive whistling or whining noise is caused by the rush of air through the compressor at high speeds during spool up or boost conditions. Blow-off valves vent this pressurized air to reduce the whistling.

How much boost can an engine handle?

There are no fixed limits. Engine components must be robust enough to handle more stress. More boost requires tighter tolerances, better materials, proper fueling, and engine management. Conservative boost levels are commonly used for reliability.

Can turbos be added to diesel engines?

Modern diesels frequently use turbocharging to boost power and torque while controlling emissions. Both gasoline and diesel engines benefit from turbos but require appropriately engineered systems.

How long do turbochargers last?

With proper maintenance and operation within design limits, turbochargers can often last over 100,000 miles. Following the manufacturer’s oil change intervals and avoiding excessive heat are vital.

Conclusion

A turbocharger allows an engine to push more air into the combustion chambers, enabling more fuel for bigger explosions to create more power. It uses the engine’s exhaust to spin a compressor that forces extra air into the cylinders. Benefits of turbocharging include increased horsepower, torque, engine efficiency and altitude performance along with enabling engine downsizing. The turbo stays dormant until activated by rising RPMs, then works harder as engine speed builds. Modern turbos employ complex control systems for smooth, predictable power delivery free of lag. With quality engineering and regular maintenance, turbochargers provide tremendous performance benefits

- Are Avocados Good for You?

- Why Can’t My Budgie Fly Properly?

- Did Lapu Lapu Fight Magellan?

- Can Sheen Be Added to Flat Paint?

- Were Pop Tarts Banned in the UK?

- How to Start a Teeth Whitening Business?

- How Does Amex Travel Insurance Work?

- How Can You Tell When You Started Following Someone on Instagram?

- Does Yeast Have Catalase?

- Who Treats Vagus Nerve Disorders?

- What Is Saifi Saidi Caidi?

- How to Watch Redzone on Sling TV?

- What Is the Survival Rate for Turner Syndrome?

- how many calories do you burn playing pickleball?