Key Takeaways

- Measure gap between cabinet and wall to size shim

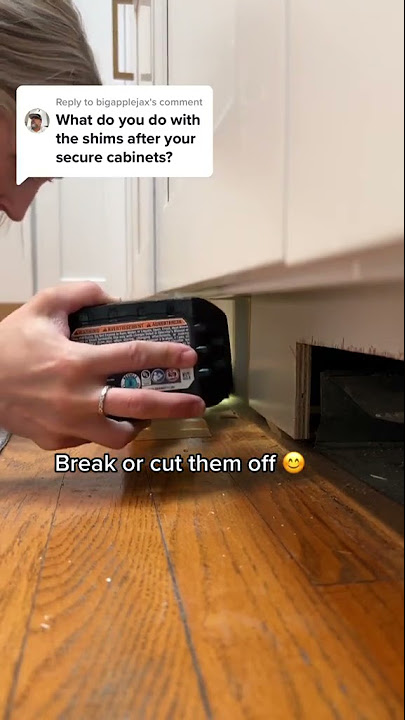

- Cut shim with saw or knife for snug fit

- Test fit shim and trim if needed

- Secure shim with adhesive or screws

- Repeat for each shim to level cabinets

Introduction

Installing kitchen cabinets or bathroom vanities is an important home improvement project. Getting them level and secure makes a big difference in how they look and function. One key step is cutting and placing shims under the cabinets. Shims are thin pieces of material that go between the cabinet and the floor or wall. They fill any gaps and help level and stabilize the cabinets. This article will explain everything you need to know about how to cut shims for cabinets.

Learning this simple home improvement skill will ensure your cabinets turn out straight, sturdy, and looking great. With the right techniques and materials, cutting shims for cabinet installation can be easy. The information here will walk you through the entire process in a step-by-step way.

By the end, you’ll be able to measure, cut, fit, and install shims like a pro. Level cabinets lend a polished look to any kitchen or bath. This article gives you the knowledge to do it yourself and avoid the hassle and cost of calling in a carpenter. So read on to learn this useful skill and improve your DIY abilities.

Step-by-Step Guide on Cutting Shims for Cabinets

How do I measure and size the shims I need?

The first step is to measure the gap between the cabinet and the wall or floor. This will determine what thickness of shim you need. Use a tape measure to accurately measure the depth of the space.

Be sure to measure at several points along the bottom or back of the cabinet. This will account for any unevenness in the floor or wall. Once you know the gap width, add 1/8 to 1/4 inch. This allows for a snug fit when you install the shim.

Having the right shim thickness is key. If it’s too thin, it won’t fill the gap properly. If it’s overly thick, it can lift the cabinet up too high. So accurate measuring is important for proper shim sizing.

What tools do I use to cut the shims?

You can cut shims in a few different ways using basic workshop tools. The most common options include:

- Handsaw – A fine-toothed backsaw or miter box saw works well for carefully cutting shim pieces to size.

- Utility knife – A sharp utility knife is ideal for trimming and shaving thinner shims once cut to fit.

- Miter saw – A power miter saw quickly cuts pieces of wood dowel or molding to length for shims.

- Table saw – A table saw can cleanly rip long boards into thin shim strips if needed.

For safety, always wear gloves and eye protection when using saws to cut shims. Make sure to secure the wood firmly while cutting to prevent slipping.

How do I make sure the shims fit tightly?

Fit is very important when installing shims. They need to fit snugly without too much play or wiggle room. Here are some tips for getting a tight fit:

- Cut shims slightly larger at first. It’s easy to trim them down for a perfect fit.

- Use a utility knife to shave the shim and fine tune the thickness after test fitting.

- Cut shims so the grain runs perpendicular to the cabinet edge. This prevents splintering.

- Plan to use at least 3 shims spaced evenly to support each cabinet side.

- Stagger shims so gaps don’t align and weaken support.

Taking a bit of extra time to fine tune the fit of each shim will pay off later. Snug fitting shims won’t slip or shift easily when you install and level the cabinets.

How do I secure and install the shims?

Once the shims fit snugly, it’s time to secure them in place under the cabinets. Here are two good options:

- Construction adhesive – Use small dabs of adhesive at both edges to glue the shim to the cabinet and wall/floor.

- Trim head screws – Drill pilot holes and drive trim head screws through the cabinet into shims and framing.

Install shims at every location a cabinet will attach to the wall or sit on the floor. Space multiple shims evenly along each side or base panel. Secure permanently with adhesive or screws.

What materials can I use to make shims?

There are a few good options for the material to make your own shims:

- Wood – Hardwood like oak or maple makes durable shims. Pine works too but may compress over time.

- Plastic – Shims made of rigid plastic won’t rot or warp. They resist moisture well.

- Cedar – Shims cut from cedar are lightweight and resist shrinking and warping.

- Fiberboard – Dense fiberboard shims are economical and less prone to swelling.

- Metal – Copper or aluminum flashing can be shaped and cut into very thin shims.

Wood and plastic shims are most common. Choose a stiff, sturdy material that won’t compress easily when squeezed. This maintains the tight fit. Cedar and treated woods have natural rot resistance.

Can I use pre-cut shims for cabinets?

Yes, you can purchase shims pre-cut to common thicknesses if you prefer. Look for packs of cabinet shims sold specifically for home improvement projects. They often contain a range of widths like 1/8”, 1/4”, and 3/8” in standard lengths.

Pre-cut shims from cedar or plastic can save time. But you may still need to custom trim some shims to fit a particular gap. Having a variety of thicknesses makes it easier to find the right size.

How do I use shims effectively when installing cabinets?

Here are some tips for working with shims during cabinet installation:

- Fit shims starting at the high corner to level the run. Shim each subsequent cabinet.

- Tighten the cabinet lightly to the wall, then add shims for an accurate fit.

- Level front-to-back before fully securing by lifting the front and adding shims in the rear.

- Use a shim every 16-24 inches including adjacent to every screw or nail location.

- Make final leveling adjustments with the shims before permanently securing cabinets.

Take your time placing and adjusting shims as you install cabinets. They allow you to fine tune until everything is perfectly plumb, level, and square.

- How Can You Tell When Someone Checks Your Location?

- What Animal Is Goofy? Dog or Cat?

- How to watch full episodes of married at first sight?

Conclusion

Learning how to accurately measure and cut shims is an essential skill for installing kitchen cabinets or bathroom vanities. With the right techniques, you can create a set of custom fitted shims. Key steps include measuring gaps, cutting shims to fit snugly, securing them properly, and using enough to fully support all cabinets.

Preparing high quality shims ensures your cabinets end up stable, secure, and perfectly level. Take it slow and double check the fit of each shim. With patience and the proper materials, cutting shims for cabinet installation can be easy. Your cabinets will maintain the right position for years to come

- What Was the Purpose of the Curiosity Rover?

- how big is the non volley zone in pickleball?

- Why Do Redheads Have Yellow Teeth?

- Why Does My PS4 Sound Like a Jet Engine?

- How to Cover a Bruise Effectively?

- Are Poppies Poisonous to Touch? (Explained)

- How to Get Polestar 1 NFS Heat?

- Is Whooping Cough Still Around?

- How to Uncover White Out Text?

- Can You Wear Molded Cleats on Turf?

- What Is Overcontrolled Personality Traits?

- How to Start a Teeth Whitening Business?

- Are Foam Rollers Good for Your Back?

- Does the Stromberg Have a Boost in GTA Online?

- Does Navionics Work with Lowrance?