Europium is a rare earth element that has important applications in lighting, electronics, and other technologies. But where does this unusual metal come from and how is it extracted? This comprehensive article will explore the key methods used to obtain europium from ores and transform it into a usable form. By the end, you’ll have an in-depth understanding of the fascinating process of europium extraction.

Key Takeaways on Europium Extraction

- Europium is commercially extracted using ion exchange and solvent extraction from ores like bastnasite and monazite.

- Metallic europium can be obtained by reacting europium (III) oxide with lanthanum or mischmetal.

- Zinc reduction and electrolysis can reduce europium (III) to europium (II), which can then be precipitated.

- Fractional crystallization helps separate europium from other rare earth elements.

- The extraction process must occur under an inert gas like argon or nitrogen.

- How Can We Reduce Food Waste in Schools?

- Where Is Treponema pallidum Found??

- Is Predation an Abiotic or Biotic Factor?

Introduction

Europium is one of the rarest elements on Earth, making up just 0.0001% of the crust. But this elusive metal has become vitally important in technology, providing the red phosphor used in TVs and computer monitors and the blue phosphor in fluorescent lamps. With the growth of LED lighting, europium is also used in small amounts to produce the pure color light.

But before any of these applications are possible, europium must be extracted and refined. This is an extremely challenging process due to the similarities between europium and other rare earth elements. Separating them requires complex chemical processing.

This article will provide a comprehensive overview of the key methods used commercially and in laboratories to extract europium from ores. You’ll gain an in-depth understanding of processes like ion exchange, solvent extraction, lanthanum reduction, and more. We’ll also cover how europium is converted to a usable form. With China producing over 90% of the world’s rare earth metals, the intricacies of europium extraction are essential knowledge.

By the end of this piece, you’ll understand the tremendous effort and chemical processing required to isolate small amounts of europium from complex ore sources. You’ll appreciate the value of this elusive element and its importance across numerous industries. So let’s dive in and demystify the extraction of europium!

The Basics: Europium Ores and Chemistry

Before examining extraction methods, it’s helpful to understand where europium is found and key chemical properties that make it challenging to isolate.

Europium is not found in nature as a free element. Instead, it occurs chemically bonded in rare mineral ores along with other rare earth elements. The two primary europium ores are:

- Bastnasite: A mixed lanthanide fluoro-carbonate mineral found in large deposits in China and the United States.

- Monazite: A rare earth phosphate mineral mined heavily in China, Australia, Brazil, and India.

Both these ores contain a mixture of rare earths including cerium, lanthanum, neodymium, and europium. Concentrations range from 0.1% to 0.2% for bastnasite and around 0.2% for monazite.

Chemically, europium commonly occurs in a +3 oxidation state, though the +2 state is also accessible under certain conditions. But most significantly, europium is very similar in chemical behavior and properties to several other rare earth elements near it on the periodic table.

This makes separation incredibly challenging and complex chemical processing is required to isolate even small amounts of high-purity europium. With this context of europium’s natural occurrence and tricky chemistry, let’s explore the key extraction methods.

Method 1: Ion Exchange and Solvent Extraction

On an industrial scale, the dominant method to extract europium from ore sources is using ion exchange resins combined with solvent extraction. This allows europium to be purified and separated from other rare earths.

The process involves several key steps:

- Acid leaching: The raw europium ore is finely ground and then treated with sulfuric acid. This leaches out the rare earths including europium into a soluble sulfate form.

- Concentration: The leachate goes through a process of concentration and filtration to remove impurities and obtain a purified rare earth sulfate product.

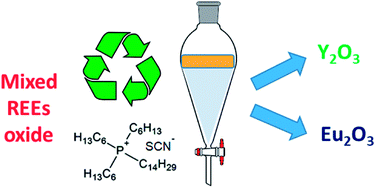

- Solvent extraction: Organophosphorus extractants are added to strip out and separate the rare earths into fractions. Several stages of extraction are used to maximize separation.

- Ion exchange: The extract containing europium is circulated through resin columns that retain europium while letting other rare earths pass through.

- Precipitation: Once sufficiently isolated, europium is precipitated out of the ion exchange eluate using oxalic acid. The final product is europium oxide (Eu2O3).

This multi-step ion exchange and solvent extraction process allows europium to be separated from ore sources on a large scale. It is estimated to capture over 95% of the europium. The resulting europium oxide can then be reduced to pure metallic europium.

Method 2: Reaction with Lanthanum or Mischmetal

In addition to ion exchange, there are chemical methods that can be used to obtain metallic europium in the lab.

One approach is to react europium (III) oxide with lanthanum metal or a lanthanum-cerium alloy known as mischmetal:

- Eu2O3 + 2 La → 2 Eu + La2O3

The reaction proceeds at temperatures between 500-1000°C under vacuum conditions. The lanthanum or mischmetal acts as a reducing agent, giving up electrons to reduce the europium (III) to europium (0).

This straightforward process allows the europium metal to be separated from the resulting lanthanum oxide byproduct. The purity of the extracted europium depends on the purity of the starting materials. Repeated reactions may be done to improve the yield.

While not suitable for large-scale production, this reduction method is commonly used in lab settings to produce small quantities of metallic europium for research purposes.

- Where Specifically in the Situation Is the Partial Point of View?

- Was Magdalene Mary’s Last Name?

- Why Is It Called Potluck? The Fascinating Origins and Evolution of the Communal Dining Tradition

Method 3: Zinc Reduction

Another chemical reduction process uses zinc metal to convert europium to its metallic state. There are a few different variations of this method:

- Zinc reduction: Europium oxide is blended with zinc powder and heated to over 600°C under vacuum. Zinc acts as the reducing agent:Eu2O3 + 3 Zn → 2 Eu + 3 ZnO

- Zinc/amalgam reduction: The europium oxide is mixed with zinc and mercury to form an amalgam. Heating the amalgam forces the zinc to give up electrons.

- Electrolysis: A salt like europium chloride is electrolyzed to deposit europium metal onto the cathode.

In each case, metallic europium can be extracted by distilling and condensing the product. These zinc reduction methods are simple and reasonably effective for producing small lab samples of europium metal. However, the product may have significant zinc impurities if the process is not optimized.

Method 4: Precipitation as Europium (II)

While europium predominantly exists in the +3 state, it can be reduced to +2 using very strong reducing agents like zinc or sodium amalgam. Europium (II) has some substantially different properties from the +3 state. This allows it to be selectively precipitated out from other rare earths.

Once europium has been reduced to the 2+ state, precipitation methods can include:

- Adding sodium carbonate to precipitate europium carbonate

- Adding barium sulfate to co-precipitate europium with barium sulfate

These techniques take advantage of the divalent chemistry of europium (II) to isolate it from remaining trivalent rare earths in solution. The precipitate can then be treated to recover high-purity europium.

- Where Is Osteitis Pubis Pain?

- Which Books Are in Dickensian?

- Are Mergers or Acquisitions More Common & Why?

Method 5: Fractional Crystallization

The final key method of separating europium from rare earth mixtures is fractional crystallization. This involves:

- Dissolving the rare earths in a solvent like nitric acid to form a solution.

- Cooling the solution slowly to precipitate crystals of nitrates in sequence based on solubility.

- Separating the crystal fractions containing heavier, less soluble elements like europium.

Repeated crystallization and separation steps are performed to isolate and purify the europium fraction. This is a time and labor intensive process, but can give high purity europium compounds.

Converting to Usable Europium Metal

Once europium has been extracted from ores and separated using the above techniques, it is commonly converted to the metal form.

This involves reducing europium compounds to the elemental state using hydrogen or calcium reduction. The europium metal obtained through chemical extraction is over 99% pure but contains trace amounts of other metals.

To prepare high purity europium for industrial uses, zone refining or distillation are used to reduce impurities to less than 1 ppm. The final europium metal is soft, silvery-white, and ready for incorporation into lighting, displays, and electronics.

- What Does Suprachoroidal Mean?

- How Much Is Lvn Program at Concorde?

- How to Support the Perineum During Delivery?

Protecting Against Oxidation

Throughout the extraction and refinement process, protecting europium from oxygen and oxidation is critical. To maintain europium in the desired +2 or +3 oxidation states, all steps are performed under an inert atmosphere.

This is achieved by using glove boxes or shut reaction vessels filled with inert gases like:

- Argon

- Nitrogen

These inert conditions prevent undesirable oxidation and allow careful control over the europium chemistry. Maintaining a non-reactive atmosphere is essential for maximizing the yield of europium from rare earth sources.

Key Takeaways on Europium Extraction

We’ve covered a lot of ground on the intricacies of europium extraction. Let’s recap the key points:

- On an industrial scale, europium is commercially extracted from bastnasite and monazite using ion exchange and solvent extraction. This method yields over 95% purity.

- In the lab, europium can be obtained through chemical reduction using lanthanum, zinc, or other reducing agents. This produces small batches of metallic europium.

- Precipitation techniques take advantage of the unique +2 chemistry of europium. Fractional crystallization can also separate europium from rare earth mixtures.

- The final europium metal must be protected from oxidation by inert gases like argon during processing steps. This maintains the desired oxidation states.

Europium extraction is a complex process but utterly essential for supplying this unique element for modern technologies. This article has demystified the intricacies of safely extracting europium from challenging ore sources rich in rare earth elements. You now understand the tremendous effort and chemical processing required to isolate rare europium.

- Which Immunoglobulin Is Present in Breast Milk?

- How Is an Esker Used?

- How Do Aldehydes React with Sodium Bisulphite?

Key References:

- Gupta, C.K. and Krishnamurthy, N. (2005). Extractive metallurgy of rare earths. CRC press.

- Krishnamurthy, N. and Gupta, C. (2016). Extractive metallurgy of rare earths. CRC press.

- Jordens, A., Cheng, Y.P. and Waters, K.E. (2013). A review of the beneficiation of rare earth element bearing minerals. Minerals Engineering, 41, pp.97-114.

- What’s a Throwaway Statement?

- How Much Does It Cost to Scotchgard a Sofa?

- Why Does My PS4 Keep Saying Copying Add On?

- How To Reset Ford F150 Screen?

- Are Hackzall and Sawzall Blades Interchangeable?

- When Can You Shoot Cormorants?

- What Sheen for Ceiling Paint?

- How to Get Mythical Capos in the Idle Mafia?

- are badminton and pickleball courts the same?

- Which Protocol Interacts Asynchronously over UDP?

- How to Open a Soda Machine Without a Key?

- Does VA Require Impounds?

- What Is Dreamtime Aboriginal? An In-Depth Explanation

- How Much Is a Replacement Key for Acura Tl?